Introduction

Today is #WorldBakingDay, so lets talk about wastewater within the bakery industry and how we can help reduce it…

For modern bakeries, wastewater is a touchy subject. An unavoidable consequence for creating the confectionaries that we all love. Behind the counter, is an ongoing effort to reduce the wastewater created by the manufacturing process and unavoidable daily washdown procedures. When manufacturing baked goods, water is used as a solvent and dispersing agent for salt, sugar and yeast. Avoiding the use of water in baking is impossible.

The Issue at Hand

The concern with wastewater created from bakeries, is the associated output consisting of Chemical Oxygen Demand (COD), Total Suspended Solids (TSS) and Fats, Oils & Greases (FOG) which when dispersed into local waterways, act as pollutants creating blockages and contamination.

COD traditionally is high due to the elevated level of sugars and other substances used in production. COD can be difficult to remove as it requires extensive chemical treatment. FOG is also commonly found in baking processing / manufacturing yet is straight forward to remove as, due to the nature of its buoyancy, rises meaning it can be scraped away with fair ease. Though, some fats, oils and greases can be emulsified requiring chemical treatment. Lastly, total suspended solids can be reduced heavily using pre-screening as well as further treatment systems which we will elaborate on further.

Let’s talk numbers…

Data collected from our previous bakery manufacturers and processing customers showed:

Average COD Quantity = 7,500 mg/l

Average FOG Quantity = 754 mg/

Average TSS Quantity = 1,200 mg/l

After treating the wastewater, we observed the following reductions:

Average COD Quantity = 2,250 mg/l (-5,250)

Average FOG Quantity = 8 mg/l (-746)

Average TSS Quantity = 12 mg/l (-1,188)

The Benefits of Treating your Wastewater

Above, we can see huge reductions across the board. But what are the benefits to these cutbacks? Firstly, the ongoing cost of wastewater discharge to your local water authority can be staggering. By treating the wastewater prior to discharge these costs can be significantly reduced, in some cases by as much as 70%.

Additionally, reducing your wastewater output can ensure local water authority consent limits are consistently achieved; preventing prosecution through fines and shutdowns. This means your site can continue to operate freely and without fear of government regulators.

Finally, as we all know, sustainability is key in modern manufacturing. As years role on, businesses and consumers alike, are becoming more aware of carbon footprint, waste output and environmental exploitation. By managing your wastewater, you are, in essence, promoting a sustainable practice. So, treating your effluent is not just good for your business, its good for the environment too.

How Can I Start Treating my Wastewater?

Beginning this process is made straight forward by our 2-step procedure:

1) Sending us a sample of your wastewater. This can include a visit to your site by one of our Watermark Projects engineers for a feel of your set up, operation and to take an effluent sample for analysis. However, you can also send us a sample of your wastewater so we can analyse it here, at your headquarters in Manchester.

2) Based on your wastewater sample, we can provide a solution which can include several different strategies tailored to your requirements.

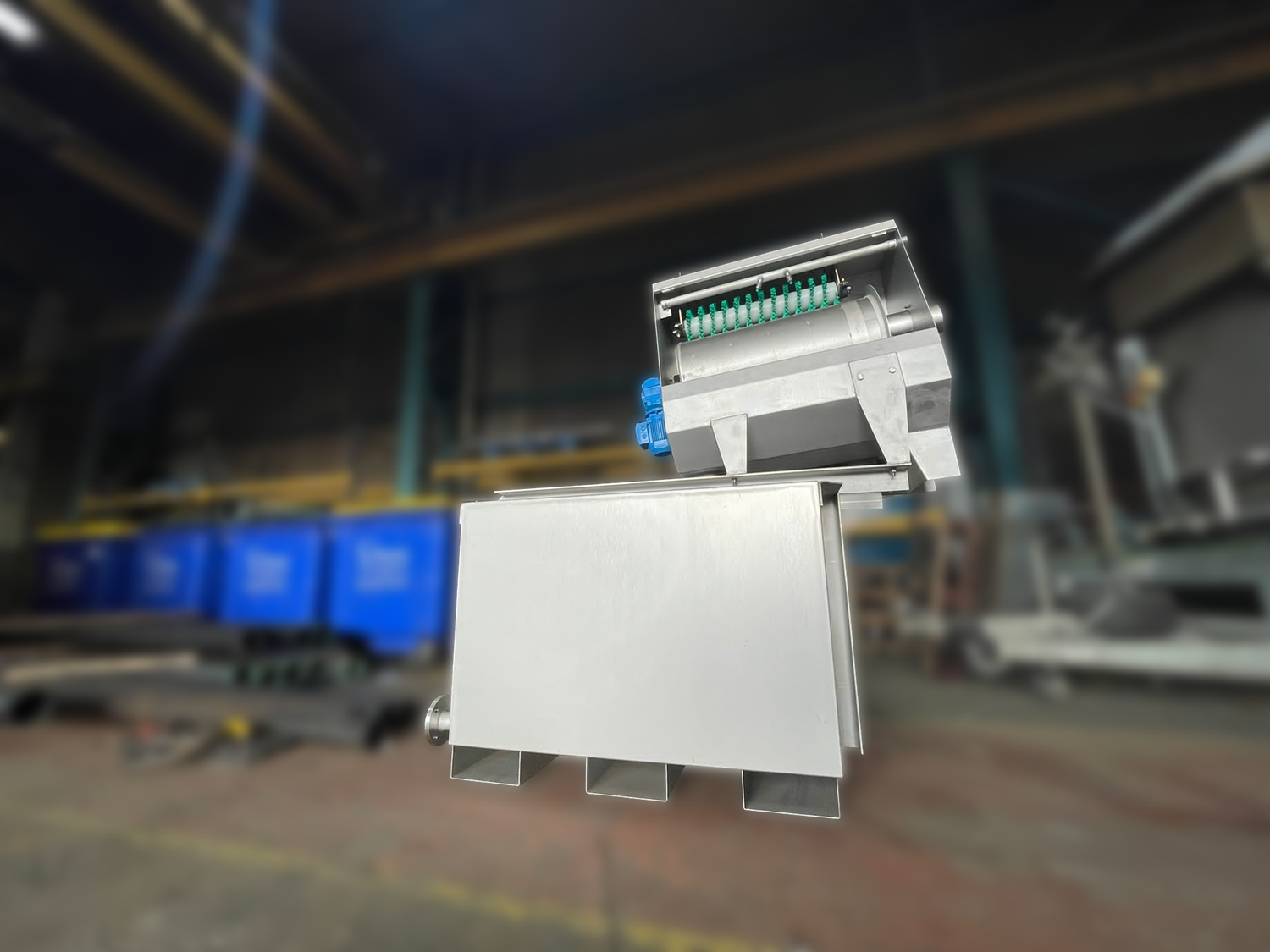

Strategies can include automated Pre-Screening which target gross solids reduction as a primary line of defence before moving onto further treatment solutions. Our pre-screens are designed and manufactured in-house and come with the option for a high, mid or base level mount which can also involve access steel where necessary.

Additionally, our flagship Dissolved Air Flotation (DAF) range offers a complete wastewater treatment solution. Designed for the effective removal of COD, TSS and FOG; the DAF range is our most efficient and all-encompassing solution. These units can work in conjunction with our pre-screens, sludge de-waterers and balance tanks. All designed to streamline your wastewater treatment process.

To wrap things up, we offer constant support alongside our products. Should you run into any hiccups, we can advise, offer solutions, spares, maintenance and constant support. We are here to help in any way we can!

For more information on how we can treat your wastewater, see our small scale representation here: https://youtu.be/1wBOOGQ-YfQ

Curious? Good. Give us a call or email, we’d love to have a chat:

01204 574 721

www.watermarkprojects.co.uk